SWL series Trapezoid screw Worm Gear Screw Jack

As one of the worm screw jack manufacturers, suppliers, and exporters of mechanical products, We offer worm screw jack and many other products.

Please get in touch with us for details.

Mail:[email protected]

Manufacturer supplier exporter of the worm screw jack.

Screw-Worm Jack or screw lift lifts widely used in machine building, metallurgy, construction, irrigation equipment and other industries, is starting up, and dropped through accessories advance, overturned and position adjustment and other functions at various altitudes. SWL is a worm screw-lift crane components foundation with compact structure, small size and light weight. Sources extensive, no noise, easy installation, the use of flexible, multi-function, supporting forms, high reliability, long life and many other advantages. Can be single or in combination, can be controlled accurately in accordance with certain procedures to enhance or promote the adjustment of height Motor power can be used directly or can also be manually operated. It’s a form of structure and assembly, and the height can be customized user requirements

Product Description

Technical data:

1. Lift speed: 150mm/min~1800mm/min

2. Input power:0.5 -21.8KW

3. Screw rang: 5-16 mm

4. Bearing range: 2T-100T

5. Structure: motor direct connection, single & double shaft

Characteristic:

Standardize & series design

Reverse operation

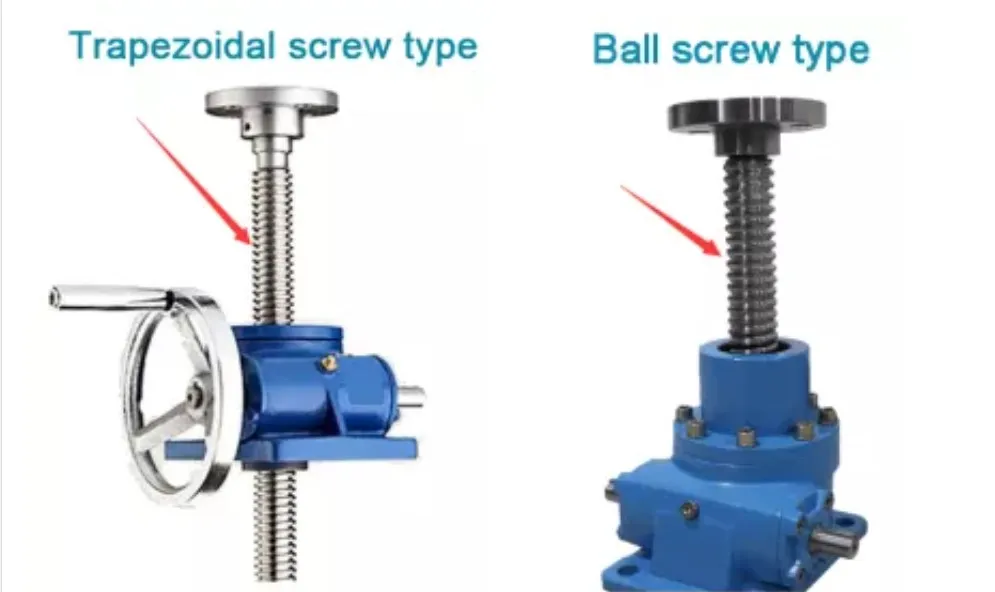

1.SWLM (Trapezoid screw)

SWLM (trapezoidal screw) is suitable for low speed and low frequency.

Main components: Precision trapezoid screw pair and high precision worm-gears pair.

Economical: Compact design ,easy operation, convenient maintenance.

Low speed, low frequency:Be suitable for heavy load, low speed, low service frequency.

Self-lock: Trapezoid screw has self-lock function, it can hold up load without braking device when screw stops traveling.

Note:Braking device equipped for self-lock will be of malfunction accidentally when large jolt & impact load occur.

2. SWLB (General ball screw)

SWLB (General ball screw) is suitable for high speed, high frequency and excellent performance.

Main components: Precision ball screw pair and high precision worm-gears pair.

High efficiency: Rolling friction improve efficiency greatly, only a little drive power can generate great thrust force.

High speed:Rolling friction speed up travel of screw easily.

Lifetime longer: High precision ball screw can make SWLB’s lifetime longer by 3 times comparing with SWLM.

Note ;Braking devices or motor with braking devices are necessary when choosing SWLB

|

Model |

SWL2.5 | SWL5 | SWL10 | SWL15 | SWL20 | SWL25 | SWL35 |

| Max Capacity (KN) | 25 | 20 | 100 | 150 | 200 | 250 | 350 |

| Lifting screw | Tr30*6 | Tr40*7 | Tr58*12 | Tr58*12 | Tr65*12 | Tr90*16 | Tr100*20 |

| Ratio (P) | 6:1 | 8:1 | 23:3 | 23:3 | 8:1 | 32:3 | 32:3 |

| Ratio (M) | 24:1 | 24:1 | 24:1 | 24:1 | 24:1 | 32:1 | 32:1 |

| Raise per revolution (mm) (P) | 1.0 | 0.875 | 1.565 | 1.565 | 1.56 | 1.5 | 1.875 |

| Raise per revolution (mm) (M) | 0.250 | 0.292 | 0.5 | 0.5 | 0.5 | 0.5 | 0.625 |

| Start torque on lifting screw at max load | 250 | 385 | 500 | 400 | 490 | 850 | 820 |

| 400 | 770 | 1000 | 800 | 980 | 1700 | 1640 | |

| Starting torque/Handwind torque at max load (Nm) (P) | 18 | 39.5 | 119 | 179 | 240 | 368 | 464 |

| Starting torque/Handwind torque at max load (Nm)(M) | 8.86 | 19.8 | 60 | 90 | 122 | 217 | 253 |

| Running efficiency (%)(P) | 33 | 23 | 20.5 | 20.5 | 19.5 | 16 | 18 |

| Running efficiency (%) (M) | 11 | 11.5 | 13 | 13 | 12.8 | 9 | 11 |

| Weight without spindle or protection tube (Kg) | 7.3 | 16.2 | 25 | 25 | 36 | 70.5 | 87 |

| Weight of lifting screw 100 mm (kg) | 0.45 | 0.82 | 1.67 | 1.67 | 2.15 | 4.15 | 5.20 |

| Lubrication |

ZGN-1 or ZGN-2 (-20-+100) |

||||||

| Grease quantity | 0.1 | 0.3 | 0.5 | 0.5 | 0.75 | 1.1 | 1.9 |

Do you need screw jack of ball screw or trapezoidal screw?

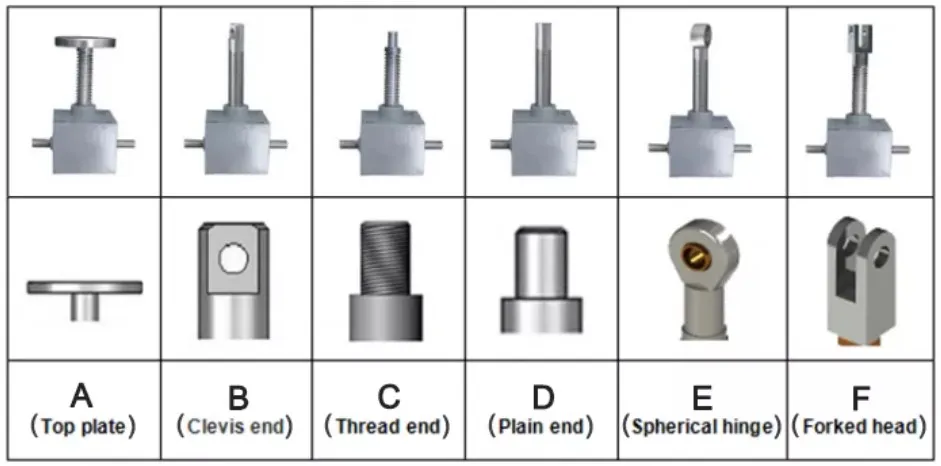

Which the screw top? you need,as picture above?

Manual type (Hand wheel?driven) or electric motor driven type or both driven type?

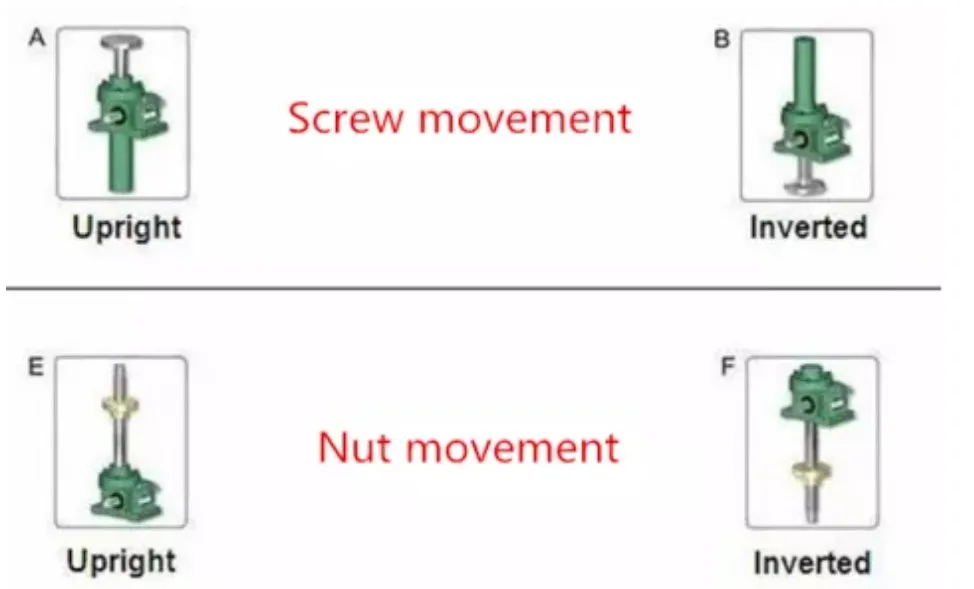

Traveling screw (screw travelling up and down when working) or traveling nut ? (the nut travelling up and down when working),Upright or?Inverted?